Vital for the auto industry when it comes to design and quality assurance for production parts and tooling.

With advancements in EV battery technology, Industrial CT Scanning has become a key player for failure analysis and more.

Capture the intricate details of physical prototypes and existing components.

This data can then be used to create digital models for further design refinement and prototyping.

When manufacturers need to reproduce or modify existing components, 3D scanning assists in reverse engineering.

Scanning a physical part creates a digital model that can be manipulated and optimized for improved performance or integrated into new designs.

1. Real-world case studies, emerging trends, and advancements offer a glimpse into a future where these technologies are a necessity for excellence in the auto industry.

2. Innovative technologies and expertise ensure safer, more reliable vehicles on the road.

You'll find all the detailed service information you need in one brochure.

Download Brochure

A major consumer product company struggles to develop, approve, and launch multiple high-level cavitation molds for high-volume production & global distribution.

Computed tomography and value-add services from Nel PreTech.

Client saves $1 million in direct cost and gains $60 million in cash flow four months sooner.

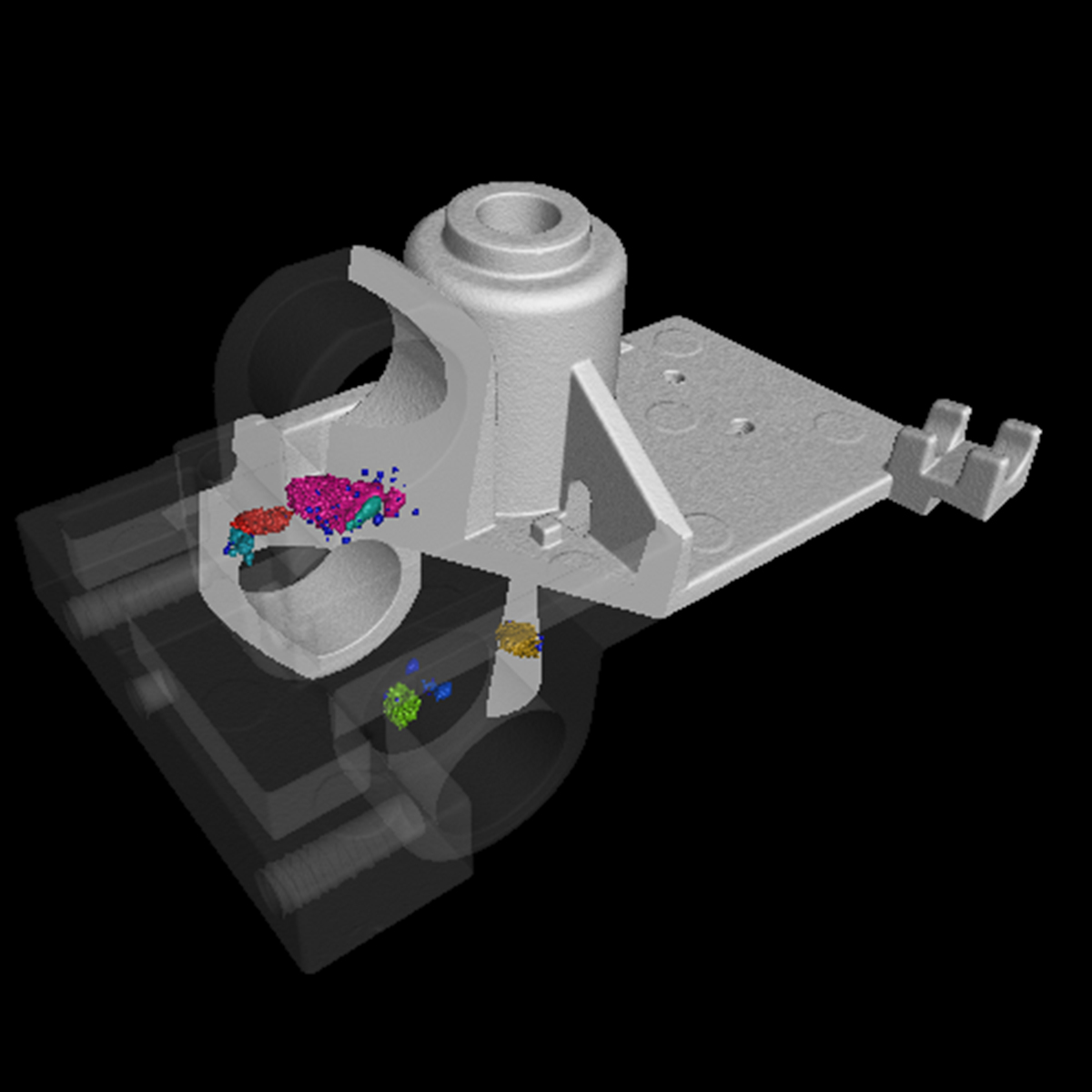

Major grill manufacturer reaches out with malfunctioning glow plugs.

Industrial CT scanning (x-ray material testing) provides digital 3D x-ray images of internal components of the glow plug & finds a wire break inside the heating device.

Client is able to investigate the root cause of the glow plug failure and fix the problem.

Global OEM medical device company needs help developing and launching drug delivery pumps.

CT scanning and value-add services create a turnkey solution to give the client a competitive advantage.

20 new tools in 20 weeks.