Industrial 3D scanning utilizes non-contact, high-resolution technology to digitally capture physical objects.

Intricate aerospace components demand precision beyond measure.

Precision in Engine Design:

Rapid Prototyping:

Quality Control for a Variety of Parts:

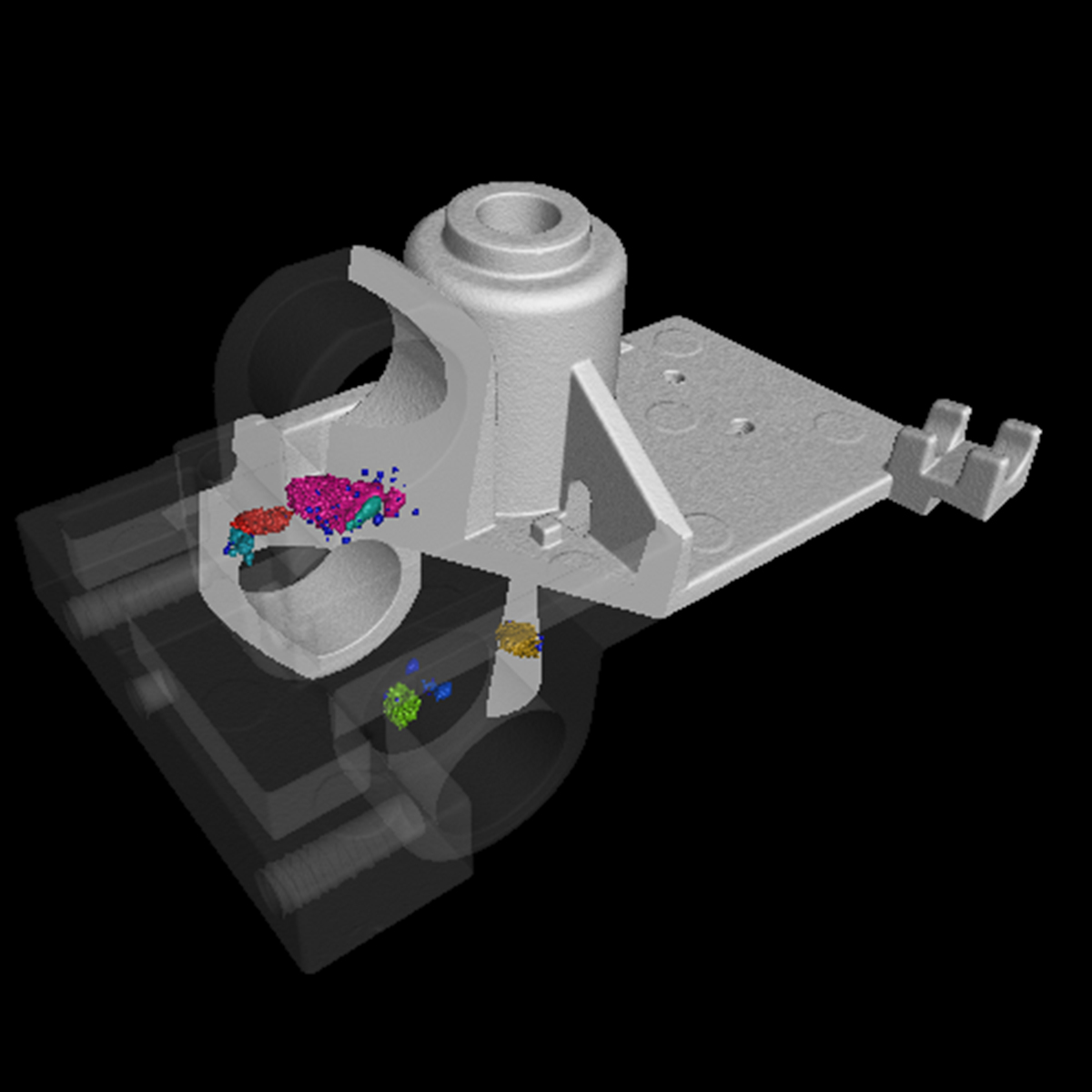

Industrial CT scanning harnesses X-rays to reveal the intricate internal structures of components, playing a crucial role in ensuring the integrity of critical aerospace parts.

Structural Integrity in Electronic Components:

Defects in Composite Structures:

Early Detection of Imperfections:

Coordinate measuring machines offer inspection services that play a crucial role in ensuring the dimensional accuracy of aerospace components.

Dimensional Accuracy of Critical Components:

Automated Inspection for Efficiency:

Guarantee Compliance with Industry Standards:

1. Real-world case studies, emerging trends, and advancements offer a glimpse into a future where these technologies are a necessity for excellence in the aerospace industry.

2. High level engagement with an expert staff to help you navigate the inspection results.

You'll find all the detailed service information you need in one brochure.

Download Brochure

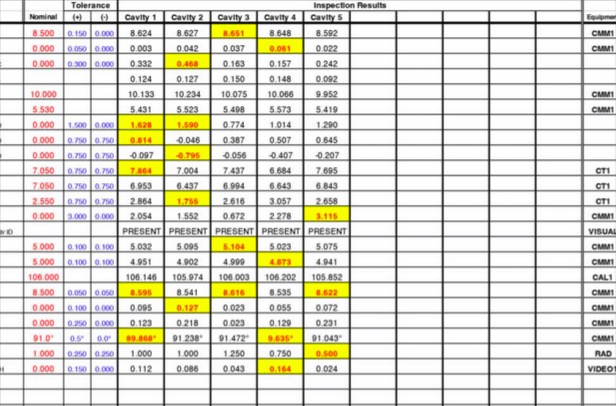

A major consumer product company struggles to develop, approve, and launch multiple high-level cavitation molds for high-volume production & global distribution.

Computed tomography and value-add services from Nel PreTech.

Client saves $1 million in direct cost and gains $60 million in cash flow four months sooner.

Major grill manufacturer reaches out with malfunctioning glow plugs.

Industrial CT scanning (x-ray material testing) provides digital 3D x-ray images of internal components of the glow plug & finds a wire break inside the heating device.

Client is able to investigate the root cause of the glow plug failure and fix the problem.

Global OEM medical device company needs help developing and launching drug delivery pumps.

CT scanning and value-add services create a turnkey solution to give the client a competitive advantage.

20 new tools in 20 weeks.