Access inner details and features of manufactured parts and assemblies with high-end 3D scans.

Solve problems in minutes not months with fewer process and tooling change iterations from one single scan.

Make confident decisions with accurate data & reporting, thorough analysis, & expert support.

Luers, Drug Delivery, Medical Implants, Dental Hardware, Medical Connectors

Electric Vehicles, Batteries, Farming & Mining Equipment, Recreational Vehicles, Marine

Manifolds, Pumps, Nozzles, Electronics, Fuel Chambers

Packaging, Disposable Cutlery, Sporting Goods, Tech Manufacturing

Die Casting, Metal Stamping, Plastic Injection Molding, Metal Injection Molding

3D Printing, Rapid Prototyping, Direct Manufacturing, Tooling

Firearms, Weapons Systems, Hypersonics, Ammunition, Military Components

Establishes:

You'll find all the detailed service information you need in one brochure.

Download Brochure

A major consumer product company struggles to develop, approve, and launch multiple high-level cavitation molds for high-volume production & global distribution.

Computed tomography and value-add services from Nel PreTech.

Client saves $1 million in direct cost and gains $60 million in cash flow four months sooner.

Major grill manufacturer reaches out with malfunctioning glow plugs.

Industrial CT scanning (x-ray material testing) provides digital 3D x-ray images of internal components of the glow plug & finds a wire break inside the heating device.

Client is able to investigate the root cause of the glow plug failure and fix the problem.

Global OEM medical device company needs help developing and launching drug delivery pumps.

CT scanning and value-add services create a turnkey solution to give the client a competitive advantage.

20 new tools in 20 weeks.

Just to be clear, there are perhaps upwards of 50 different x-ray techniques for various uses, most of which are not commercially deployed or available. For your purposes, we are talking about Computed Tomography scanning industrial products. This is sometimes referred to as x-ray material testing.

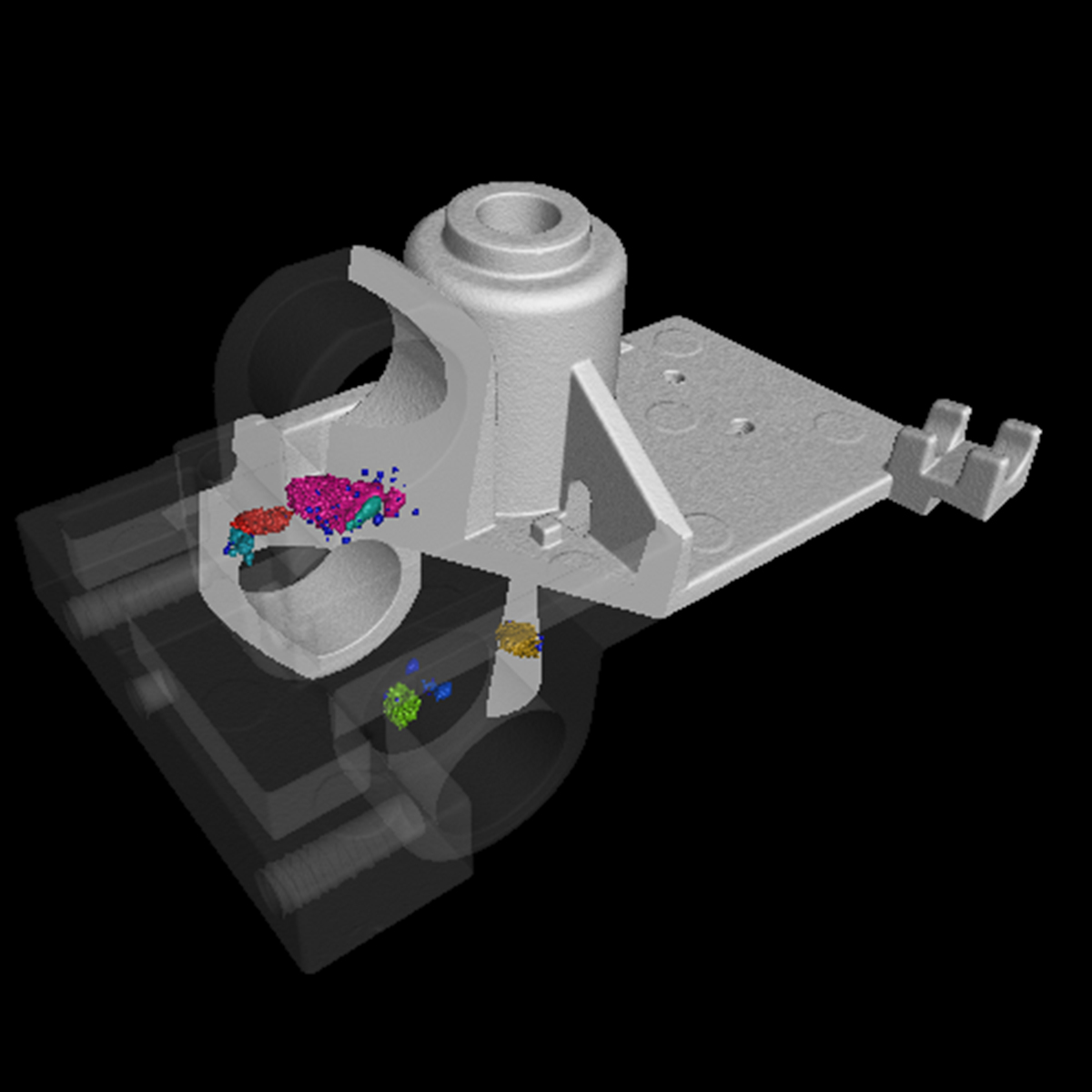

The object is placed on a rotary stage with a cone beam, low energy x-ray source which projects a beam of x-rays onto the sample object. A flat panel, x-ray detector on the opposite side of the source collects the data. The data can then be exported into specialized software developed for a multitude of analysis capabilities.

A Computed Tomography scan or CT scan is a set of voxel data (volume pixels) created from a compilation of 2D slice radiographic images. The result of this compilation is a 3D rendering that allows industrial users to completely analyze the interior and exterior geometry of a part or assembly. The reasons and opportunities for such analysis are engineering and quality driven and grow every day.

Industrial CT scanning makes use of computer-processed combinations of many X-ray measurements taken from different angles to produce cross-sectional “tomographic” images (virtual slices) of specific areas of a scanned object. This allows the user to see inside the object without cutting. Since Computed Tomography scans do not rely on line-of-sight to acquire geometry data, there is nothing missing from the scan as in structured light or laser scans.