Reverse engineering modeling methods are the methods used to create models of existing products, systems, and components based on their functionality, structure, and behavior.

Two popular types of reverse engineering modeling methods are as-built and design intent.

What is As-Built Reverse Engineering Modeling?

As-built reverse engineering modeling involves creating a digital model of an object or system by analyzing its current state. Here are the steps involved in the process.

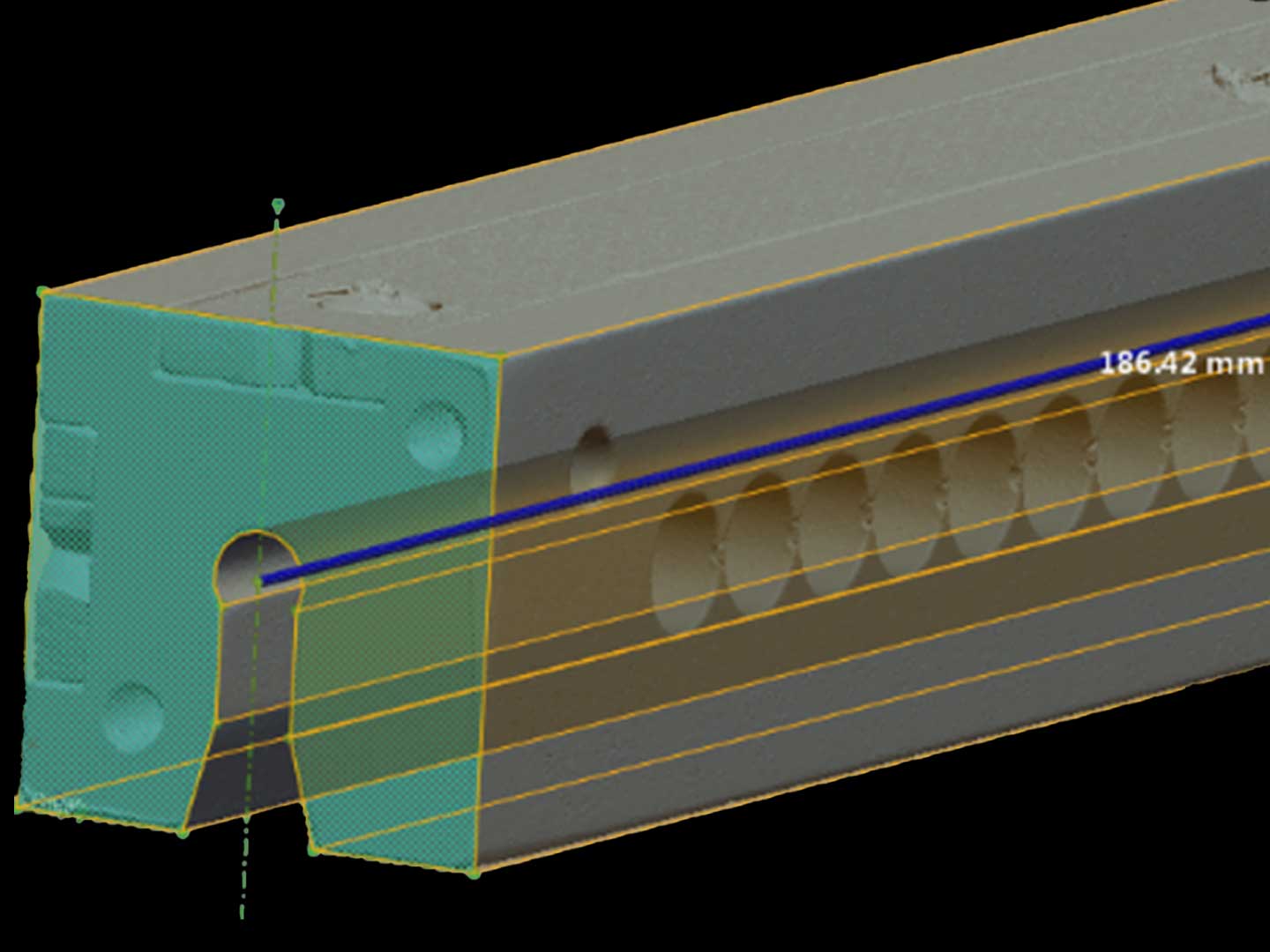

➢ Data Collection: All information about the object to be reverse engineered is collected. The design engineer records datapoints of the object using metrology-grade scanning equipment.

➢ Digitization: The collected data is digitized using 3D scanning for reverse engineering software.

➢ Data Processing: The digitized data is processed and converted into an appropriate format.

➢ Modeling: Engineers use CAD software to create a 3D model of the object. The model is compared with the object to ensure its accuracy.

➢ Documentation: Once the dimensional accuracy of the 3D model is verified, engineers note down technical specifications, material properties, assembly instructions, and any other relevant information.

Design-Intent Reverse Engineering Modeling Defined

Design intent is another commonly used reverse engineering modeling method. It is useful when dealing with complex objects or systems, especially if the original documentation is missing or incomplete. Here is an overview of the method.

➢ Data Collection: The engineering team gathers as much information about the product as possible. The team studies the features of the object as well as assemblies and sub assemblies.

➢ Functional Analysis: Engineers try to understand the intended function of each component and how parts interact with each other.

➢ Design Reconstruction: CAD models, diagrams, and other representations that explain the essential features of the object are created to recreate the original design intent.

➢ Validation and Iteration: The team uses the available data to validate the reconstructed design. Based on their observations, engineers refine the design as needed.

➢ Documentation: The recreated design intent is documented.

Choosing the Right Reverse Engineering Modeling Method

Though both the as-built and design-intent reverse engineering modeling methods have advantages, one method may be more appropriate in some cases than the other.

Consider these things when deciding which of the two reverse engineering modeling methods to use.

➢ Project Goals: If your goal is to create a dimensionally accurate replica of apart or product, use as-built reverse engineering modeling. In case you want to re-create damaged, incomplete, or legacy parts, design intent is the ideal reverse engineering modeling method.

➢ Available Resources: If you do not have enough time and lack the resources required to collect detailed data and carry out in-depth analyses, design intent may be a better method.

➢ Budget Constraints: As-built reverse engineering usually takes longer and isa costlier process.

➢ Future Use of the Model: If you intend to use the model as a reference when planning maintenance for the object or system in the future, as-built may be more suitable. If, on the other hand, you intend to utilize the model to create design iterations, prefer design intent over as-built.

To request a quote for our reverse engineering services, call 708-429-4887.